Craftbot FLOW IDEX XL: Leading the way for new innovative 3D Printers

In the work area 3D printer market, in general, form quality ranges in

all cases, with choices at each value point somewhere in the field of $200 and

$10,000. The less expensive ones, as a rule, have lightweight edges while the

more costly ones are just about as tough as a workbench, and casing

inflexibility altogether affects print quality. Craftbot

FLOW 3D Printer has gained notoriety for building suitable printers

that are assembled like tanks. We got our hands on the latest and a

significant, new Craftbot FLOW IDEX XL for an audit, and it's difficult to say

if it's assembled more like a tank or a high-rise.

This is presumably probably huge before it's not, at this point in the

work area classification. While the size is threatening, it's pretty simple to

unpackaged. It requires two individuals to move because of its size and weight,

and fortunately, it has lift handles that are appropriately situated close to

the top. An arrangement sheet in the case gives bit by bit guidelines that

include eliminating the security clasps for delivery and connecting the spool

holders and direct fiber cylinders; it's all around outlined and clear. Also,

it's just one page, exactly how I like my headings.

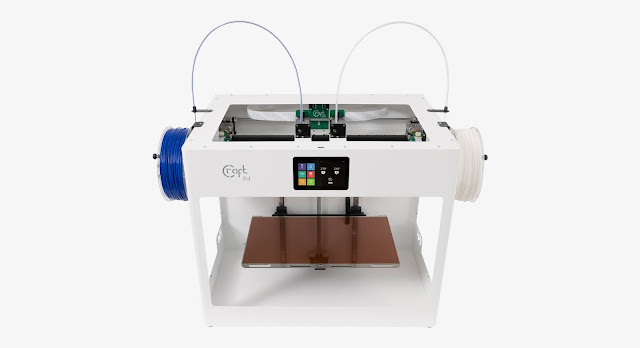

That is a 20oz container for scale. They genuinely aren't joking about the Craftbot FLOW IDEX XL. It has a form volume of 425mm x 250mm x 500mm. The littlest measurement is more significant than the most prominent element of most work area 3D printers. In any case, the Craftbot FLOW IDEX XL is certifiably not a one-stunt horse because, as we as a whole know, size isn't all that matters. IDEX represents autonomous double expulsion, which means clients can print various tones and materials just as print copy and reflected articles.

What's more, that is not all; this printer has highlights and sensors by

the drove. It has network bed levelling, fiber run out location, double drive

extruders, a locally available camera, print continue work, Wi-Fi, a

Kapton-covered attractive, adaptable/removable bed, and surprisingly a sensor

that advises you if the mattress isn't set effectively. Essentially, if a work

area 3D printing highlight exists, this printer has it. Craftbot has developed

a (500mm) high bar for themselves, so how about we check whether they can go

through it.

The Setup

There are many alignment alternatives, and I ran a large portion of

them. There are two-bed levelling steps: the initial step is helped by a test

that shows you the amount to turn every handle Flow 3d printer, and afterwards, there's a robotized network

levelling measure. The primary cycle is straightforward and intuitive, with

great visual pointers on the screen concerning how the handles should be

turned; however, the handles were challenging to ride.

I needed to utilize forceps. The subsequent cycle doesn't need any

connection, yet it takes some time because it tests numerous marks of the bed

at 60°C. At that point, it warms to 90°C and rehashes the examining it heats to

120°C and does it all once more. A careful cycle, most definitely. The solitary

thing left to do was load some fibre and get printing. Stacking fiber requires

a couple of moments by utilizing the touchscreen or by controlling the printer

through its web interface (wifi arrangement is essential after you look into

the default login data on their webpage), and the extruders heat up rapidly.

.jpg)

Comments

Post a Comment